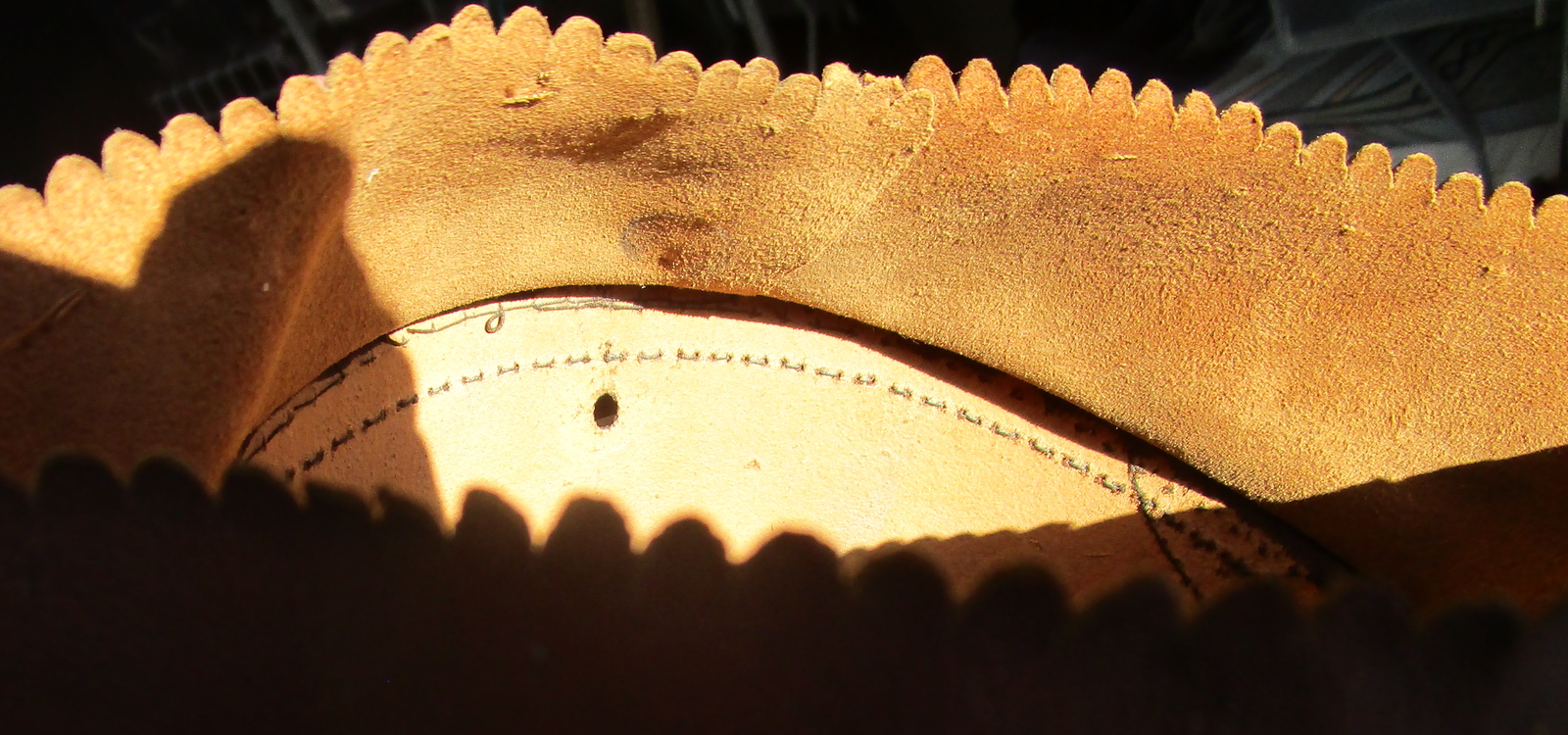

I have been working on this helmet for a couple of months. Problems: both visors need restitching, as does the officer silk liner. The front visor has been depressed after 100 years by the tail feathers of the wappen and finally, the visor has shrunk so that one end of the trim does not snug up against the leather. The "before photos":

The helmet, especially the brass fittings and wappen are very dirty.

A good photo of the "wappen depression", caused by the rotting of the visor stitching and the subsequent pushing up of the visor into the tail feathers. Again, we see how mistreated and dirty this helmet is. :x

Again, we see how mistreated and dirty this helmet is. :x

The wappen also shows 100+ years of dirt and tarnish.

The helmet, especially the brass fittings and wappen are very dirty.

A good photo of the "wappen depression", caused by the rotting of the visor stitching and the subsequent pushing up of the visor into the tail feathers.

The wappen also shows 100+ years of dirt and tarnish.