This is a great micro comparison of a larger subject, indeed.

Thanks for posting these Brian. A fun subject!

I thought a lot about what you had posted last week, concerning the higher quality and thicker metal parts on these straps being made for more elite Regiments within the German Army during the pre-war years. It got me pondering for a few days, thinking about examples I have looked at in the past, and going through my straps here at home.

Sometimes, I think too much..., must be my OCD that most career military men seem to have.

I think that some of the opinions I am about to express are probably common knowledge written in books dealing with the German Army's struggle with Standardization and Logistics. I have not read those books, but I am always happy to learn and hope other members of the site will direct me toward them!

It made me think about the plethora of different manufacturers between different German States, and the increases in the numbers forced onto those manufacturing entities during the first year of the war.

I am of the opinion that these makers in different Germanic States, followed the directives for standardization, but due to the differences in hand-manufacturing and levels and methods of production, the standardization of things as simple as M91 sideposts ended up having slightly different diameters within a few hundredths or thousandths of an inch, depending on the maker, especially between different States.

The end fittings made to fit a specific company's M91 posts would logically be too loose or too tight on a different maker's post if this logic is followed.

I base this opinion on the tiny visual differences in the posts themselves made within different German States.

While all of the M91 posts generally look similar within the Directives set down in writing from above, the posts from different maker's do look slightly different on different manufacturers helmets, especially if they are from different States.

Within German industry, these helmets had always been basically hand made, with true standardization being within one individual company only. Think of the nightmare of different pitches and sizing used in hand-drawn screws used by pickelhaube makers. Its a mess...

I believe that higher Reich-Level Inspections were not prioritized with CERTAIN pieces of kit and equipment in the pre-war era, but other pieces of kit, such as standardization of tooling and manufacturing would absolutely be a major priority for things like firearms, or projected or fired ordnance, or radio communications equipment.

I am of the opinion that the individual States, rich or poor, had been under such a centuries-long period of traditional feudalism, whereby the responsibility for the outfitting of troops had been the responsibility of the individual Duchy or Kingdom, that things had likely not changed too much, until suddenly everyone was mobilizing for the War in 1914.

1914 is a neat period for collectors like us who love ersatz helmets and all of the variations and materials you find them in.

But for the Germans it must have been a massive logistical nightmare. I bet there were a lot of Senior Logistics Officers who deeply regretted Germanys outdated use of the fuedal-style traditions of equipping different State's troops for things like pickelhauben.

I believe the M1915 helmets standardized a lot for the Germans as far as helmets go. I think they must have tightened their inspection procedures up somewhat and got the dimensions for parts working better. But I still find M91 posts that are slightly larger in diameter than the female connector strap end that I want to snap over it.

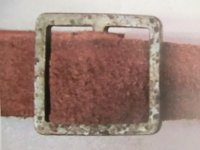

As for riveted chinstraps, every 100% original "kit-type helmet" that I have seen that has never been messed with has this type of strap.

I think that is why they are rare, and being riveted makes sense. If you think about it, there is no stitching involved at all in the "kit-type" helmets.

The maker's of the tin "kit-type" pickelhauben used a roll crimp to affix the liner onto the helmet. This makes sense, because these maker's worked in metal, not stitching like a traditional pickelhaube maker.

If they roll crimp in the liner, then why not rivet the buckles onto the straps?

And why not rivet a male and female snap into the back of the liner?

After all, it is faster and was likely approved by the contract, and a cost reduction if they are made and riveted in-house vice purchasing them elsewhere or hiring out a vendor to final stitch the straps together.

So, why bother with using stitching at all?

My opinion and 2 cents.

Bryan.