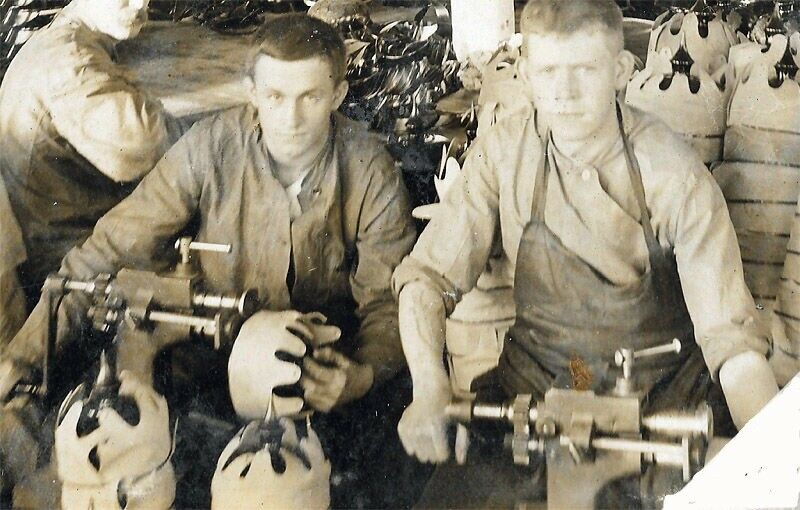

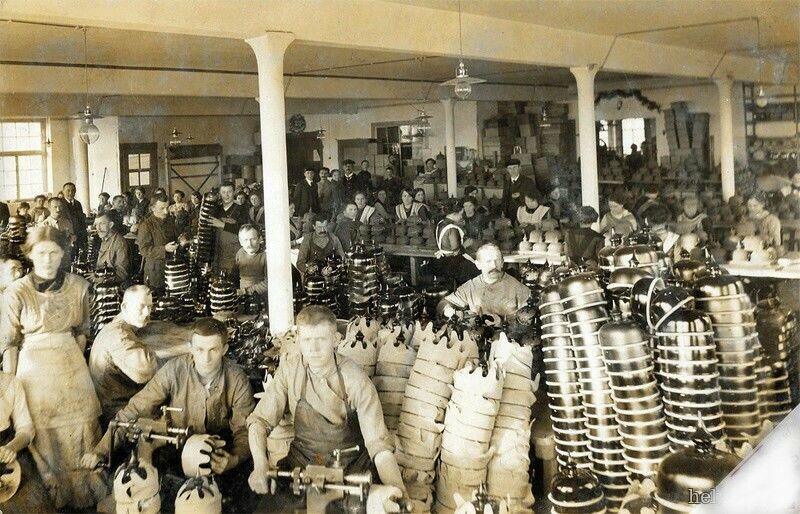

It comes to my mind, that we should establish a section here on the forum for photos like these, that show how our various helmets were manufactured. We have had other members at various times post original photos of manufacture but they are rare, and I think we should try and group them together. Regarding this photo and many of the others....they were taken during the war as part of the propaganda effort to show civilian contributions to the over all war effort. What is new for me here in these photos, is that the spike was put on the shell before the liner and the M91 side posts. I see wappen and visors on if you look closely and then I see stacks of helmets without M91 posts. So are the posts left for last so that the helmets can be stacked during production?? However, I do know for certain that these pics show liners being crimped onto tin ersatz shells. If one steps back and thinks about it, compare to the normal M95 leather helmets......the shell is stamped out (no boiling/shaping), sprayed, spike attached and then liner crimped on..no thread no sewing....dude just matches liner to slot and turns the machine crank! Good God, covid strikes again, I have nothing better to do than try to analyze old haube manufacture photos!! Stay safe everyone!